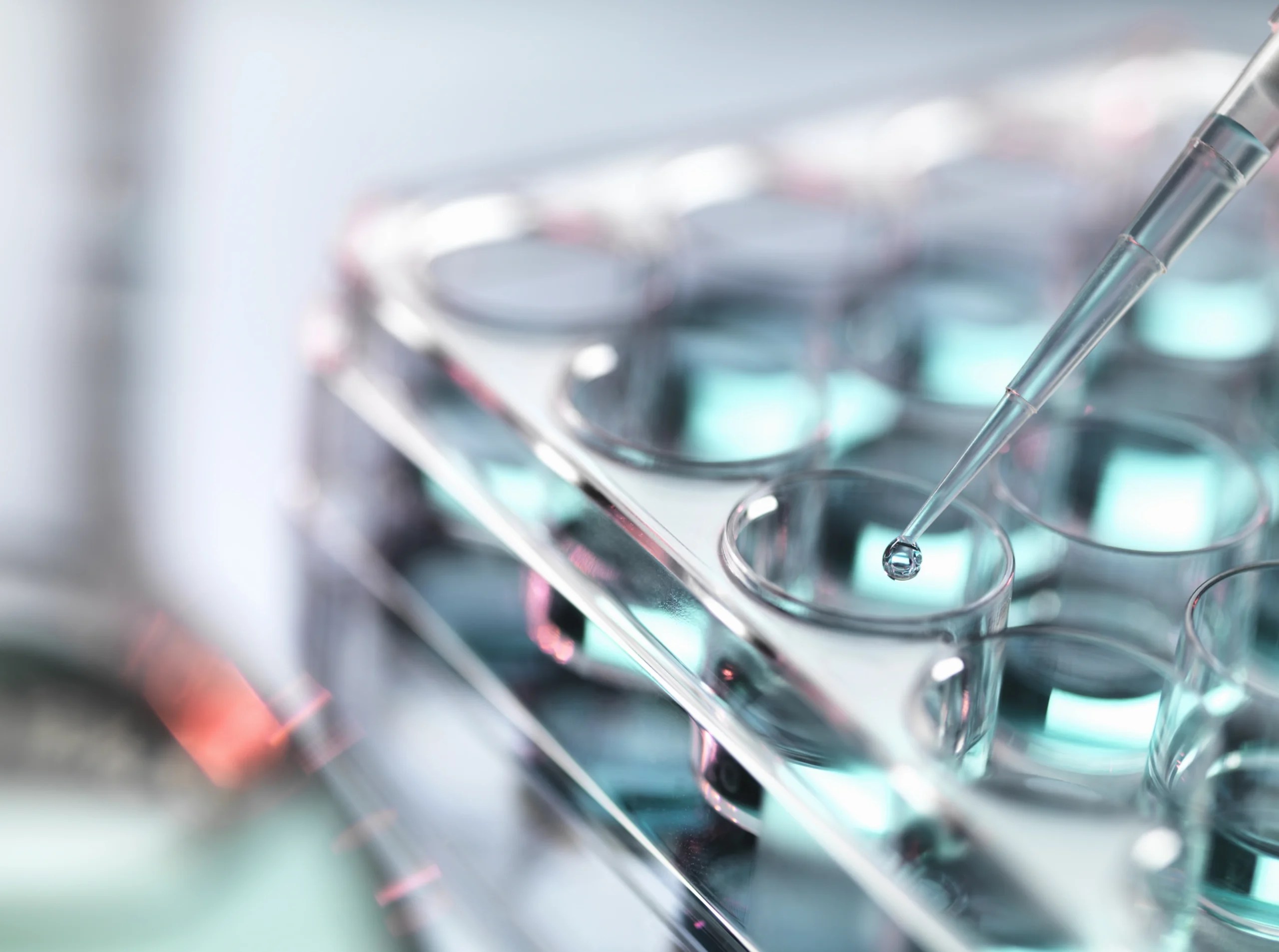

The project aimed to automate the efficient and high-throughput processing of diagnostic testing, specifically focusing on the addition of Master mix to RT-PCR plates in a newly established automated lab.

Read More Industry: Biotech/Pharmaceutical

Re:Build DAPR enhanced the calibration process of a company involved in thermometer production, resulting in increased efficiency and overall improved their manufacturing capabilities.

Read More Industry: Healthcare

A customer contracted Re:Build DAPR to create an automated biotech testing laboratory. An important subsystem of this automated lab included the elevator station. The elevator was designed to be an automated system for transferring tube racks between Pre-PCR and Post-PCR labs while ensuring environmental isolation.

Read More Industry: Biotech/Pharmaceutical

Re:Build DAPR Engineering optimized an existing machine's sorting process for delicate non-rigid porous parts by creating an advanced automated foam sorting system.

Read More Industry: Fuel Cells

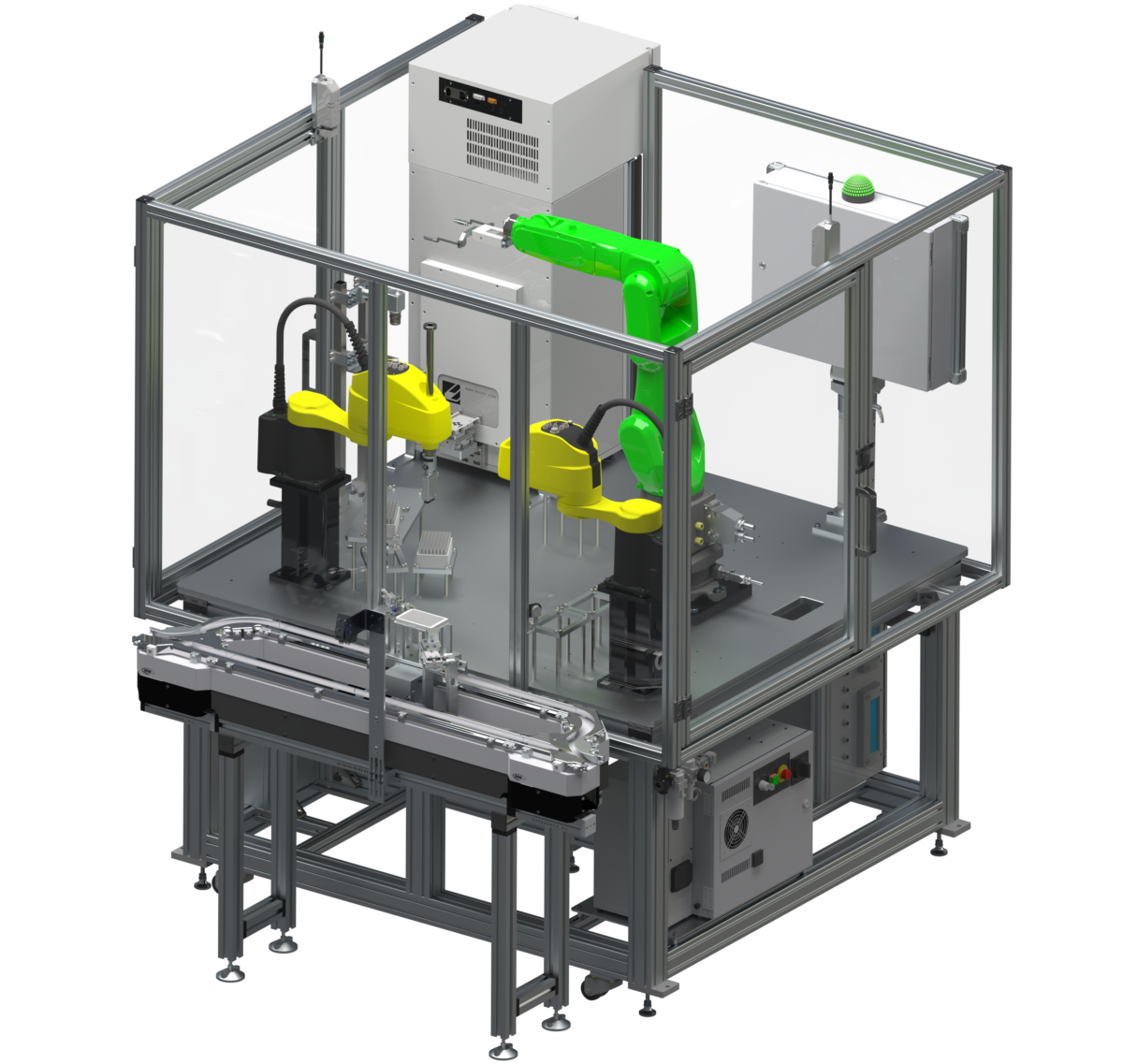

Re:Build DAPR Engineering effectively developed and implemented a high-throughput automated lab for biotech testing, featuring a Control Sample Subsystem that utilized robotics, custom-designed systems, and precise vision and barcode scanning.

Read More Industry: Biotech/Pharmaceutical

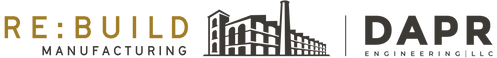

Re:Build DAPR successfully designed and built a custom manufacturing machine capable of filling and sealing over 2000 cosmetic capsules per hour.

Read More Industry: Cosmetics

Re:Build DAPR Engineering was tasked with creating an automated biotech testing laboratory. This case study explores the work done on the centrifuge station of this automated testing line.

Read More Industry: Biotech/Pharmaceutical

Re:Build DAPR successfully solved improper threading of caps onto plastic spray-bottles in a client’s automated bottling line. The approach included the retrofitting of an existing manufacturing line with a custom belt-drive solution.

Read More Industry: Consumer Products

Learn how Re:Build DAPR successfully designed and integrated an innovative automated material transport system for a client's single-pass printing platforms.

Read More Industry: Industrial Printers

Successful retrofit of a mask producing machine to also package masks at a specific rate and with minimal rejects.

Read More Industry: Manufacturing, Biomedical, Surgical Masks

Successful design of a custom automation solution for the processing of aluminum extrusions.

Read More Industry: Manufacturing

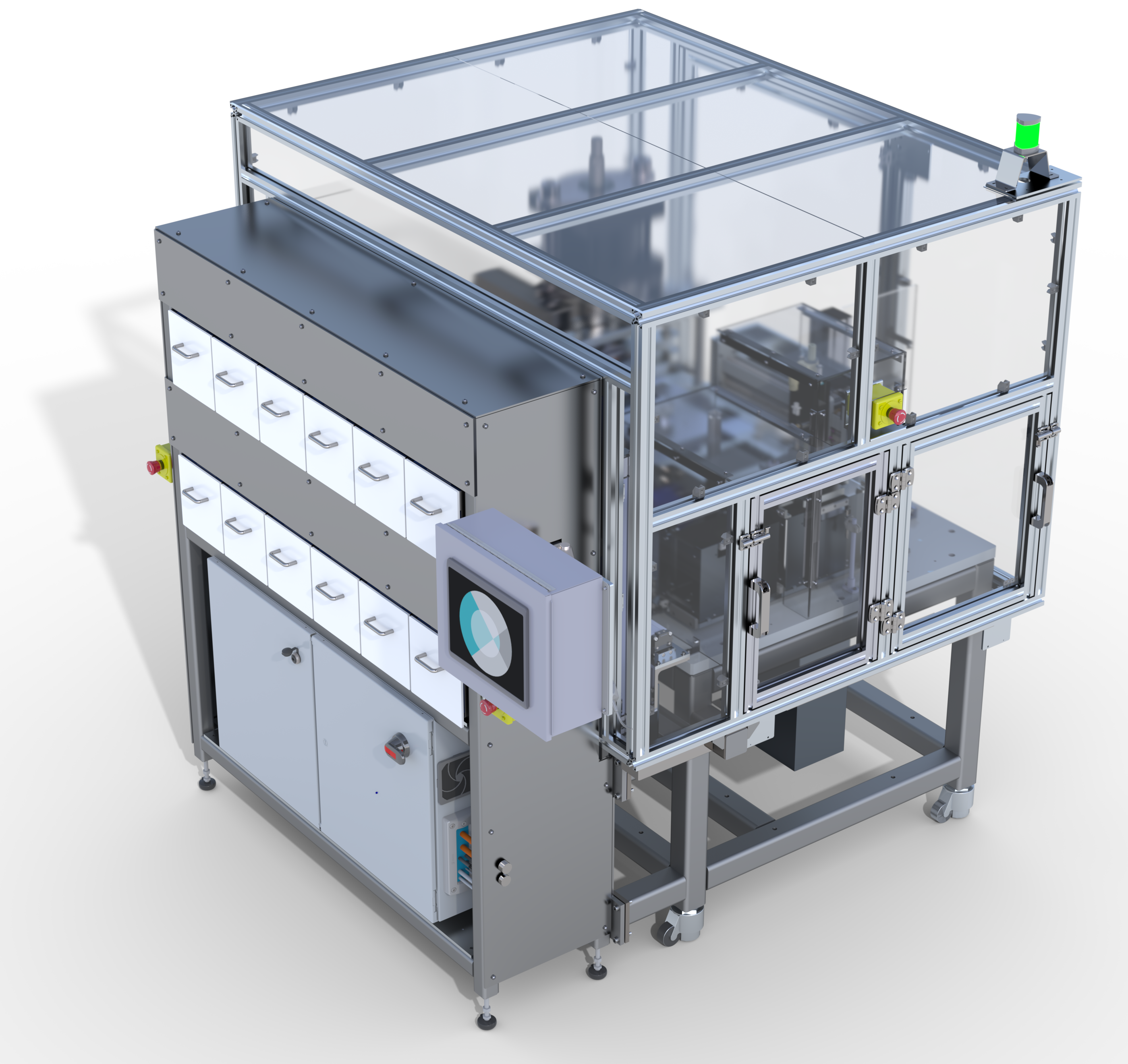

Successful integration of industrial automation to create a large-scale biotech testing lab.

Read More Industry: Biotech/Pharmaceutical

Successful design of a custom automation solution for the singulation and material handling of porous fuel cell substrate.

Read More Industry: Fuel Cells

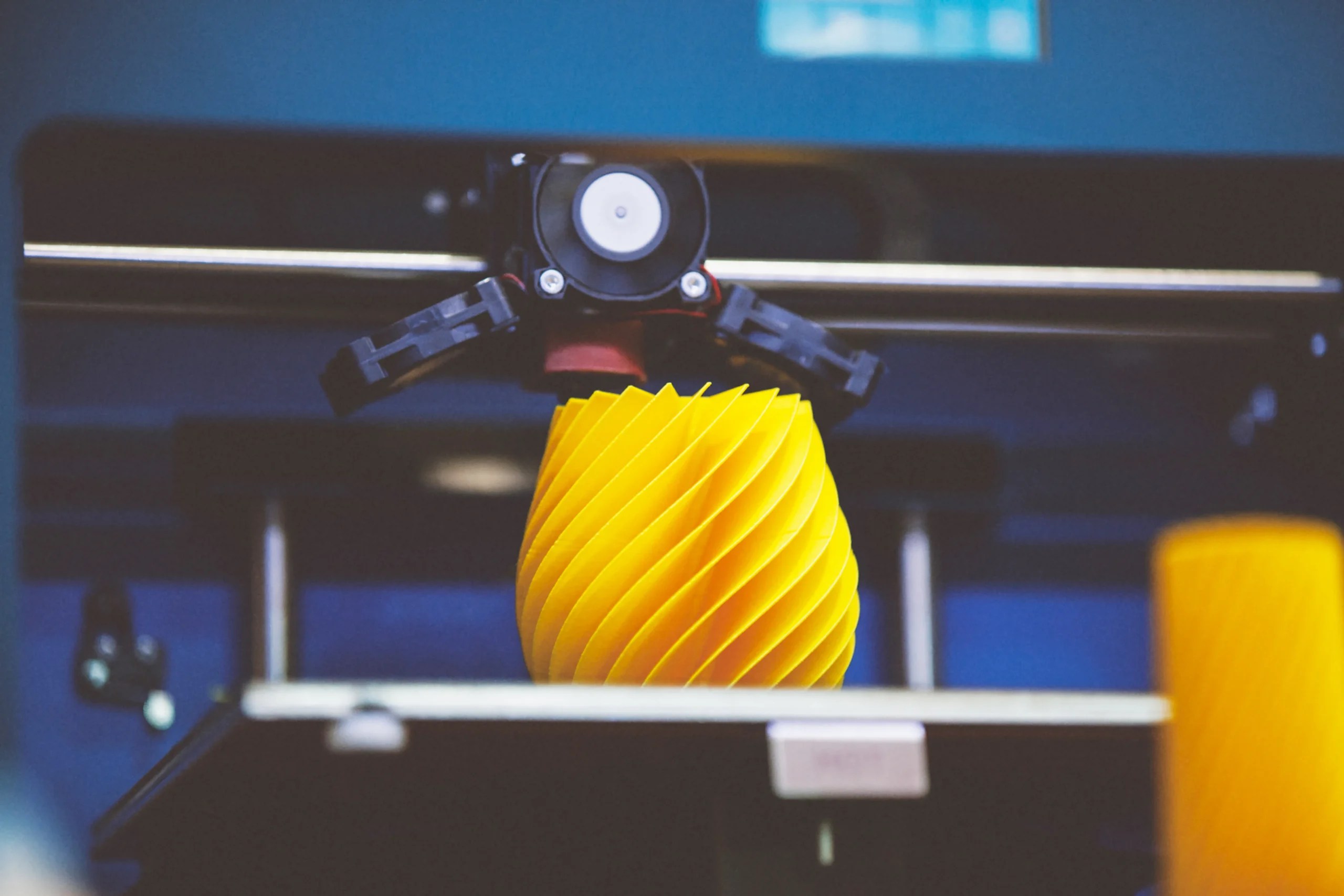

Successful commercialization of a metal 3D inkjet printing process.

Read More Industry: Additive Manufacturing