← Previous

Back to Case Studies

Summary

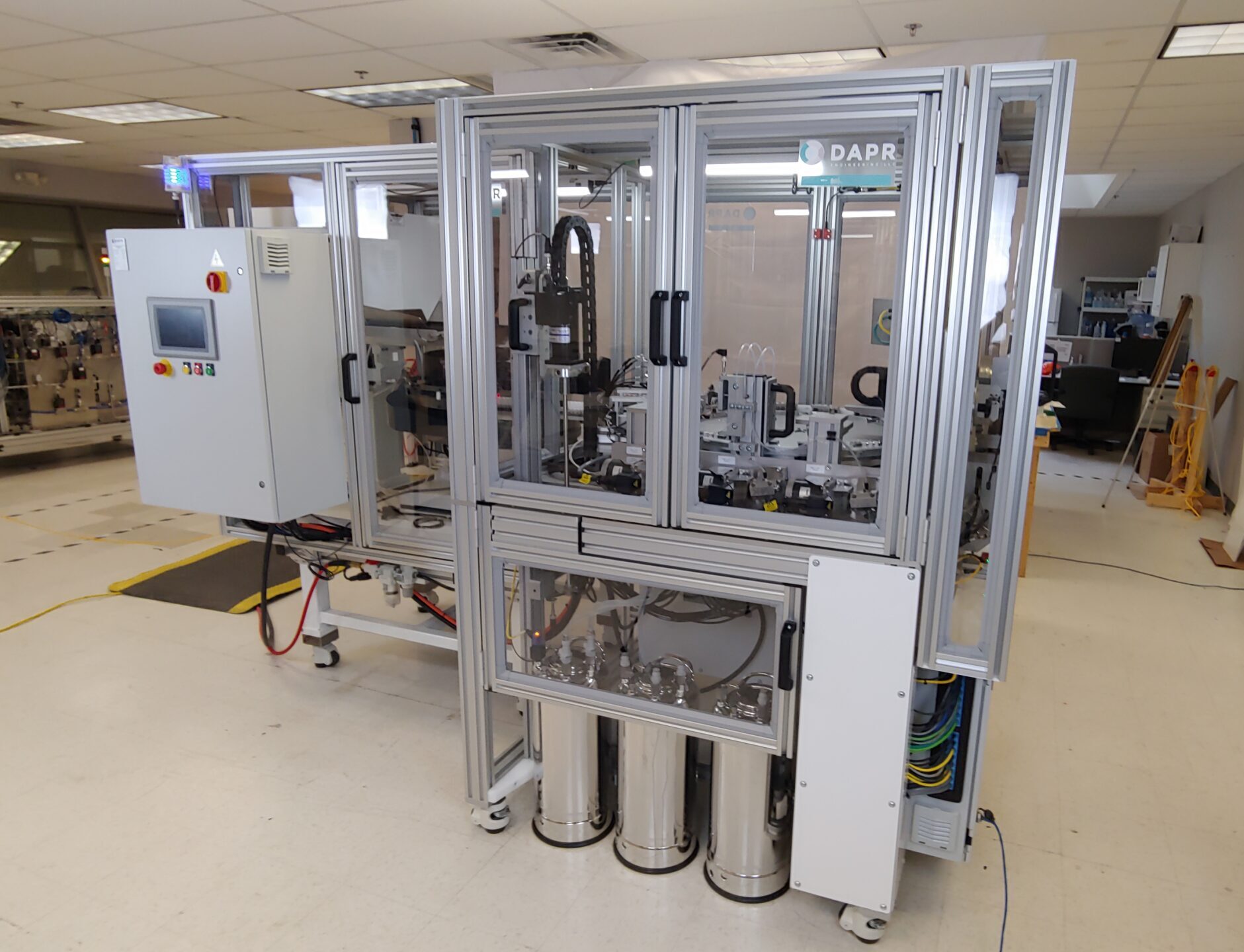

Re:Build DAPR successfully designed and built a custom manufacturing machine capable of filling and sealing over 2000 cosmetic capsules per hour.

Location: Boston, MA

Product: Capsule Fill and Seal Machine

Industry: Cosmetics

Timeframe: 10 months

Background

Our client requested an automated process to fulfill their production requirements for filling and sealing small plastic capsules with cosmetic liquids intended for consumer use. Our comprehensive solution met the client’s needs while ensuring efficient and reliable performance.Challenges & Solutions

- Capsule height variance. The height of the plastic capsules varied due to loose tolerances from the injection mold vendor. This product flaw affected the seal station due to an uneven distribution of pressure between capsules. The taller capsules would receive a higher pressure while the shorter capsules received a lower pressure causing poor seal integrity. To remedy this issue, the capsules would ride onto a height compliant base as they entered the seal station. This base had three induvial springs to compensate for the slight height variations between capsules. This creative fix ensured all capsules would receive an even distribution of pressure and heat and thus quality seals.

- Vision system’s ability to define and determine properly sealed capsules. At first, the vision system, which inspects seals for integrity and damage, failed to detect the difference between properly sealed and improperly sealed capsules. As is the case with most vision systems, this hurdle was expected, so the team prepared for additional part manipulation & machine vision learning during our integration phase. A quality seal was determined by measuring the concentricity of the outer diameter of the foil seal to the inner diameter of the capsule. In addition, the area between outer to inner diameter was inspected for changes in contrasts to determine if the product is sealed properly. To allow the system to see if the capsule was in contact with the inner diameter the team added a roller system prior to visual inspection. The roller contoured the foil seals to present the inner rim reference point on the foil for inspection.

- Thermal conductivity and material of sealing head. As part of the foil pick & place gantry, the sealing block’s main purpose is to pick foils with vacuum and heat them up to their activation temperature to be pressed and sealed onto the capsules. The intent is for the heat to be transferred from the block to the foil where the foil is properly activated and sealed. Unfortunately, the heat transfer between the block & the foil was not adequate to generate proper seals. This was due to a few root causes. First, the location of the heater, and the material of the sealing block did not make for a universal thermal gradient from capsule to capsule. This resulted in some capsules being sealed better than others. To remedy this, the team swapped the stainless-steel block with a copper block to meet heat transfer needs. Then, they added a secondary heater mirrored on the block to ensure a consistent temperature at the point of contact with the foil. Second, the material of the foil that was required to be used had a higher activation temperature to ensure sealing than the melting temperature of the capsules. The material could not be swapped out, so, the team adjusted variables of temperature, pressure & time to ensure that foils were sealed to the capsules through the melting of the top layer of the capsule ring. This maintained a quality seal without damaging the product.

Successes

The client’s objective of achieving a production rate of 1950 capsules per hour was exceeded with a sustained throughput of more than 2000 capsules per hour. Additionally, there was a notable reduction in operator involvement from 3-4 individuals required to achieve a production rate of 1300 capsules per hour down to a single operator responsible for maintaining the machine.

← Previous

Back to Case Studies