Choosing the Right Engineering Consultant

Leave a CommentSelecting the right engineering consultant is critical to meeting your project’s goals. While engineering encompasses a broad field, engineering consultants focus on a single area of expertise. Before selecting an engineering consultant, consider the specific area your business requires assistance in and ask the appropriate questions to make your choice valuable.

At Re:Build DAPR Engineering, we offer a variety of engineering consulting services in several fields of expertise. Here, we will guide you through these services, their expected costs, and common mistakes so that you can select the most beneficial engineering consultant for your needs.

Types of Engineering Consulting Services

Re:Build DAPR Engineering has engineering consultants who specialize in several areas of expertise. We offer the following engineering consulting services:

- Manufacturing Engineering

- Software Engineering

- Electrical Engineering

- Mechanical Engineering

Re:Build DAPR Engineering also offers specialized engineering services to meet your specific project needs:

- Product Development: We can guide you through each stage of development, including ideation, concept design, prototyping, and testing.

- Robotics: We can assist in designing and developing robotics for your applications.

- Automation: We can streamline your production and manufacturing processes with automation.

- Mechatronics: We can assist you in designing and developing integrated mechatronic systems, combining mechanical, electrical, and software engineering.

Cost/Fees

When we have determined the extent of the service your project or application requires, we create an agreement that includes deliverables, fee schedules, and milestones for you to sign before work begins.

Consultant fees are based on the value of the service they provide, in addition to the consultant’s cost to provide the intended services. A well-defined project scope and schedule are essential in accurately estimating the project costs as a lump sum or fixed fee. Consultants can also be paid hourly at an agreed rate, with the hours being tracked and logged. Clerical services (such as specifications, documents, and correspondence), travel, and client-consultant meetings are also billed to the client accordingly.

Common Mistakes to Avoid

When selecting an engineering consultant, these are some common pitfalls to avoid and tips to ensure your project is a success:

- Don’t make decisions solely based on cost. Instead, choose the consultant that can handle the deliverables and scope of work necessary, based on their experience.

- Don’t assume a large engineering consulting company is always better. They may not have the necessary expertise and resources to meet your specific needs. You should also understand the differences and variety of expertise, knowledge, and experience in the firm’s areas of specialization.

- Learn as much as possible about the consultant’s prior history. This includes site conditions and certifications.

- Know the full extent of the services you need. This will save you time and money, as you’ll receive the exact level of service your project requires.

- Make sure the consultant has sufficient legal understanding. Work with an engineering consultant firm that has a thorough understanding of the necessary environmental requirements, permits, regulations, and legal aspects of the project to deliver a cost-effective solution.

- Choose a collaborative consultant. They should be able to work as a team internally and incorporate feedback from you throughout every stage of the project.

Why Choose Re:Build DAPR Engineering

With an understanding of Re:Build DAPR Engineering’s areas of expertise, the costs and fees involved in engineering consulting services, and the common mistakes clients make when selecting an engineering consulting firm, you can make an informed decision to ensure a successful project.

At Re:Build DAPR Engineering, we have worked on client projects at every stage in the development life cycle. Our team has completed full machine designs, proofs of concept, alpha and beta production machine builds, and reporting and analysis of flaws in third-party production components. Our engineers can provide the assistance you need to overcome any of your business’s engineering challenges.

Contact us to learn more about our engineering consultant services.

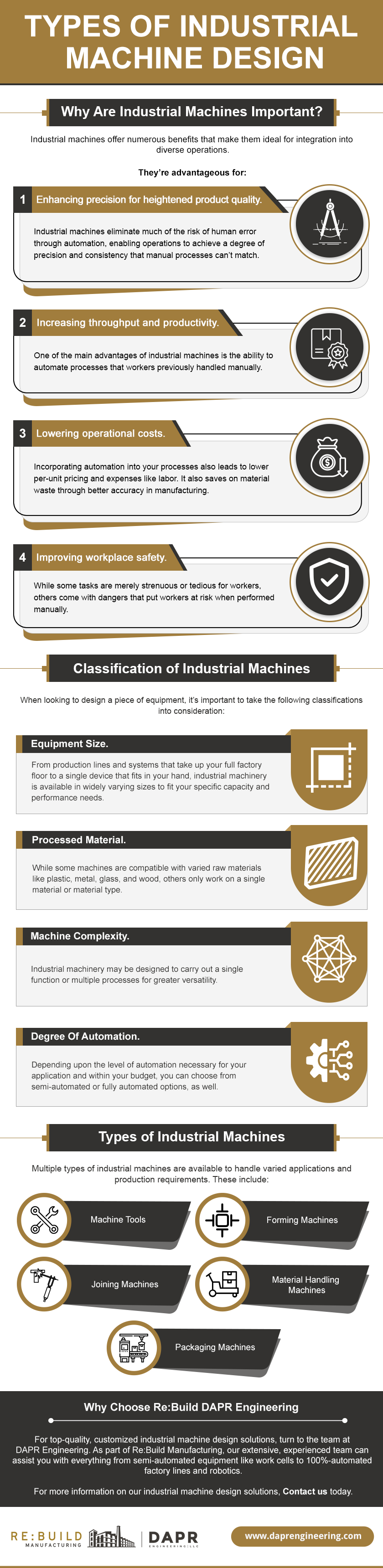

Types of Industrial Machine Design

Leave a CommentManufacturing facilities and other industrial environments need high-performance machinery to facilitate, optimize, and potentially automate operations. The ability to streamline production, however, is highly dependent upon quality industrial machine design. Selecting the right size, design, and capabilities for your machinery, in addition to choosing a trusted partner in industrial equipment design, will help give your business a competitive edge, boost productivity and profits, and much more.

Why Are Industrial Machines Important?

Industrial machines offer numerous benefits that make them ideal for integration into diverse operations. They’re advantageous for:

- Enhancing precision for heightened product quality. Industrial machines eliminate much of the risk of human error through automation, enabling operations to achieve a degree of precision and consistency that manual processes can’t match. Fewer defects equate to increased product quality, helping keep end consumers happy with the final product.

- Increasing throughput and productivity. One of the main advantages of industrial machines is the ability to automate processes that workers previously handled manually. Industrial machines don’t require breaks or vacations as humans do, allowing for increased time in production. As a result of automation, operations benefit from faster processes and increased productivity without sacrificing quality, all while freeing up staff to complete other work.

- Lowering operational costs. Incorporating automation into your processes also leads to lower per-unit pricing and expenses like labor. It also saves on material waste through better accuracy in manufacturing. Companies can then pass these cost savings on to their own customers.

- Improving workplace safety. While some tasks are merely strenuous or tedious for workers, others come with dangers that put workers at risk when performed manually. Through industrial machine automation, businesses can effectively mitigate these risks by eliminating manual tasks and maintaining a safer workspace for personnel.

Classification of Industrial Machines

When looking to design a piece of equipment, it’s important to take the following classifications into consideration:

- Equipment size. From production lines and systems that take up your full factory floor to a single device that fits in your hand, industrial machinery is available in widely varying sizes to fit your specific capacity and performance needs.

- Processed material. While some machines are compatible with varied raw materials like plastic, metal, glass, and wood, others only work on a single material or material type.

- Machine complexity. Industrial machinery may be designed to carry out a single function or multiple processes for greater versatility.

- Degree of automation. Depending upon the level of automation necessary for your application and within your budget, you can choose from semi-automated or fully automated options, as well.

Types of Industrial Machines

Multiple types of industrial machines are available to handle varied applications and production requirements. These include:

- Machine tools. Mills, lathes, and drills are common machine tool examples. These machines and those like them often remove material from a workpiece, giving it certain shapes or features with high precision. They’re also successful at finishing materials like metal.

- Forming machines. This equipment is a subset of the machine tool category and typically doesn’t remove material. Forming machines like benders or presses deform materials like metal using tension or compression force until the material takes the desired shape.

- Joining machines. As the name suggests, these machines can join two or more parts together to form a single component. Generally utilizing heated metal to achieve a joint, examples of joining machinery include soldering machines, welders, and brazing equipment.

- Material handling machines. Material handling equipment is designed to effectively and efficiently move or store various goods and materials. These machines range from pick-and-place robots and conveyors to cranes and forklifts.

- Packaging machines. Businesses use packaging equipment to prepare and secure products for shipment. For instance, wrapping, boxing, cartoning, bottling, capping, and labeling machinery assist in streamlining packaging tasks.

At DAPR Engineering, we offer design services for the above selection of industrial machines and more, providing custom options to best suit your unique application and automation requirements.

Additional Insights: DAPR’s Unique Approach to Industrial Machine Design

We do much more than simply supply industrial machines — our team works with you to design, optimize, and manufacture fully customized automation solutions to meet your individual needs, no matter how complex. It’s this commitment to customization and collaboration that sets us apart in the industrial machinery market.

Software Tools in Industrial Design

DAPR utilizes several innovative software tools to optimize equipment design. These include:

- Computer-aided design (CAD) software for detailed designs

- Computer-aided manufacturing (CAM) software for streamlining operations

- Programmable logic controller (PLC) software for efficient automation control

Elevate Your Industrial Operations With DAPR Engineering

For top-quality, customized industrial machine design solutions, turn to the team at DAPR Engineering. As part of Re:Build Manufacturing, our extensive, experienced team can assist you with everything from semi-automated equipment like work cells to 100%-automated factory lines and robotics.

For more information on our industrial machine design solutions, contact us today.