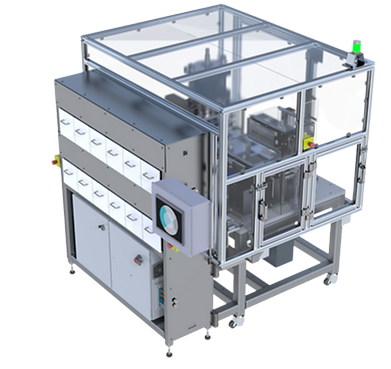

At Re:Build DAPR Engineering, we take projects from proposal to a fully functional industry-ready machine. Our team of engineers and technicians work together to build complex systems and develop rigorous testing criteria to meet your demands in your industry. We develop robust plans and follow best engineering practices to achieve project success.

Full Cycle Design to Build and Integration

- Complete project plans

- Established Statement of Work

- Defined budget

- Complete engineering cycle

Procurement

- Competitive bidding- lowest possible cost, highest quality, shortest lead times

- Vast network of suppliers across all manufacturing processes

Electromechanical Assembly

- Diverse team of electromechanical technicians who ensure functioning machines are built on time

- High precision, high quality, complex equipment

Efficient Manufacturing Practices

- Detailed plans to avoid problems later

- Designed for how it will be most easily manufactured

Functional Testing and Validation

- PM will work with you to design FATs and SATs to meet functional requirements

- Accustomed to embracing the challenge of complex manufacturing processes that require demanding testing

Single Machine to Low Volume Pre-production

- Capable of small production runs of your product

Integration

- We can work with you or a third party to design a fully integrated solution